Mining in the Prehistoric to Roman Period

This is a good ‘peer reviewed’ report that details all the mineral that can be found in the ‘open cast’ mining pits we are now finding with our Lidar survey (Mining in the Prehistoric to Roman Period)

This survey and discoveries of the frequency of these quarries and the methods used to transport them (Dykes) will revolutionise the way we interpret History in Britain (if archaeologists actually read and study the reports and surveys on my website – rather than bury their heads in the sand?)

Text by Simon Timberlake with contributions from John Barnatt, Lee Bray, David Cranstone, John ickin and Phil Newman

2.1 Non-ferrous Metals

2.1.1 Prehistory

Context

Since the late 1980s there has been an abundance of archaeological research based around field

discoveries and small to larger scale excavations at prehistoric copper mines in Britain. Twelve sites

have now been dated to the Early Bronze Age and over 30 publications have appeared (including

Dutton & Fasham 1994; Jenkins 1995; Timberlake 1990a & b, 2002a & b, 2003, 2009a & b; Timberlake

& Prag 2005). Also unpublished material including by Lewis (1990 & 1996). All but two of the sites

investigated so far (Alderley Edge and Ecton) are in Wales, where the greatest concentration of mines is

to be found (some 8 excavated and dated sites: Copa Hill, Cwmystwyth, Nantyreira, Nantyrarian, Tyn y

fron, Twll y mwyn, Erglodd, Llancynfelin and Ogof Wyddon), particularly within the mid-Wales

orefield. Most significant amongst these is Copa Hill (Timberlake 2003), but two other important mines

on the North Wales coast are Great Orme, Llandudno (Lewis 1996 unpubl) and Parys Mountain on

Anglesey (Timberlake 1990a & Jenkins 1995)1.

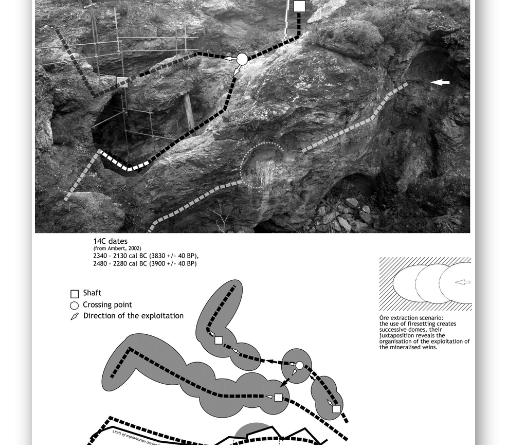

Mixtures of oxidised sulphidic ores including chalcopyrite, malachite and others – sometimes intimately

mixed with galena within the surface oxidised, supergene zones of these vein deposits – were being

worked to depths of about 10m within opencasts and up to 30m underground (within the limestone of

the Great Orme). Evidence of working methods includes firesetting and/or the use of bone or antler

picks and an assemblage of hafted and hand-held stone tools. These consist of a preferential selection of

beach cobles brought sometimes up to 25km from the coast (at Copa Hill) and recycled on site.

It is likely that the exploitation of the copper resources of the British Isles began in SW Ireland at the

Beaker-period mine of Ross Island, Killarney (O’Brien 2005) in c.2400 BC. Following the depletion and

flooding of these workings in c.1800 BC, the search for new resources of copper moved to the red bed

cupriferous deposits of the Old Red Sandstone at Mount Gabriel and other sites in south-west Cork

where prospection and small-scale mining is evident (Jackson 1968; O’Brien 1994). Then to the Isle of

Man at the copper deposits of Bradda Head and Langness, where stone mining hammers have been

found (see Doonan & Hunt 1999). On the west coast of Britain the copper and lead vein deposits within

the Lower Palaeozoic rocks of the mid-Wales uplands, along with the gossans of the massive sulphide

deposit on Parys Mountain and the Carboniferous Limestone (a Mississippi Valley type copper deposit)

began to be prospected and worked regionally c.1900-1800 BC. However, some of the mid-Wales sites

have provided earlier dates including Erglodd, c.2200 BC; Tyn y fron, 2100 BC and the earliest

exploitation of the lode outcrop on Copa Hill of between c.2100 – 2000BC.

These earlier dates deserve further examination in the context of the study of the earliest mining in Britain but what is clear is that

almost all of these mines had been abandoned and the widespread phase of prospection was over by

1600-1500 BC. This phenomenon can in part be explained by the exhaustion of easily-won oxidised ores

and the increasing depth of workings creating rising water (drainage) problems. The latter may be

linked to climate deterioration and increased precipitation, particularly within the uplands where many

of these sites were located. This inundation has been demonstrated archaeologically at Copa Hill

(Timberlake 2003). However, this is probably only part of the answer at a time when new sources of

copper, such as from the Alps were coming on stream, and political and economic allegiances were

playing important roles in this change. Future research will need to address these issues.

Just as interesting, though perhaps less surprising given the naturally well-drained limestone (perhaps

with karstic openings) of this headland, is the continuation of mining of unknown scale at the Great

Orme into the Middle Bronze Age (c.1500-1400 BC), and even into the Late Bronze Age and Iron Age.

The latter is based on the limited number of later radiocarbon dates, some of which were obtained from

the deeper parts of the mine. This Middle Bronze Age extraction may well equate with the production of

the Acton Park bronze metalwork in North Wales (Timberlake 2009a; Tylecote 1986). Northover (in

Savory 1980) also suggests that the impurity-free Type C copper of the Early Bronze Age may originate

from the Great Orme, with the low nickel and arsenic metal types B1, B3 and B4 originating from mid

and North Wales. Rohl & Needham’s (1998) work on the lead-isotope analysis of British ore deposits

suggest a correlation between the IMP-LI 6 type metal and some of the mid-Wales ores (such as from

Copa Hill) on the England & Wales Lead Isotope Outline (EWLIO) plot.

Most significant to the list of future research questions to address is the absence of evidence for

smelting sites associated with these Early Bronze Age- Middle Bronze Age mines. Archaeological

fieldwork has failed to find traces of this within the vicinity of the mines, whilst palaeo-environmental

investigations of peat basins nearby these sites have identified (copper and lead) palaeo-pollution peaks

within the peat associated with mining activity. However, it has not been possible to distinguish

whether or not these relate to smelting flume or to wind-blown dust emanating from the prehistoric

mines (Timberlake 2003; Mighall & Chambers 1993, Mighall et al 2000). Apart from roasting pits and a

number of possible but enigmatic smelting features identified by O’Brien (2005) at the Beaker mining

camp on Ross Island, Killarney, the only site from the UK which could be copper smelting, and Bronze

Age, is the largely destroyed hearth and Early Bronze Age pit containing a few grams of crushed slag

and copper prills found at Pen Trwyn on the northern cliffs of the Great Orme headland (Chapman

1997; Jones 1999).

Given the importance of what has been found in Wales, the more recent and current work in

investigating the origins of copper mining in England take on added importance, in particular as

regards what other, as yet undiscovered, sites remain and how much (or how little) of the copper from

these sites was entering the body of metalwork of the British Bronze Age. The subject of production

figures of copper from these mines, and the amount of re-cycling and import of metal, is addressed in

Copper Mining and Metal Production at the beginning of the British Bronze Age (Timberlake 2009a).

Apart from salt-working and iron production sites, and of course the incidental but significant

investigation of gravel, chalk and stone quarrying as part of what are usually seen as much broader

archaeological landscape projects, the investigation of Bronze Age copper mining over the last 20 years

has probably been the main archaeological excavation project(s) in the UK to explore mineral extraction

in the prehistoric to Roman period.

2.2 Mineral Pigments

2.2.1 Prehistoric

Alderley Edge

The possibility of prehistoric extraction of mineral pigments (chiefly malachite and azurite, but also

manganese wad, iron oxide and pyromorphite) from the Trias Bunter and Keuper sandstones of

Alderley Edge in Cheshire, has been hypothesised by Timberlake (2005a & 2009a). It may have

occurred during the Mesolithic to Early Bronze Age though so far no clear archaeological evidence has

been found. The suggested locations for this activity are the soft Bunter (Upper Mottled Sandstone) at

Pillar Mine and the interbedded mudstone horizons (containing azurite nodules) at the base of the

Engine Vein Conglomerate at Devil’s Grave and Engine Vein. The circumstantial evidence for this

includes sites of Mesolithic occupation indicated by flint scatters on the Edge. These were first described

by Roeder (1901) and recently confirmed in a survey (Timberlake & Prag 2005). They occur (perhaps

coincidentally) alongside mineral outcrops. None of these sites, including the significant one surviving

at Castle Rock (Cowell 2005) have been excavated, yet the investigation of this possible mineral and

resource connection with these Mesolithic seasonal camp sites is just one of the research questions

which should be addressed.

Forest of Dean

There may be early evidence for iron ochre pigment extraction in the Forest of Dean, Gloucestershire, in

the form of rare small hand-held cobble stone implements used as crushing stones, presumably for

hematite, some of which have been found within old ironstone mines with medieval (and probably premedieval origins) such as the Clearwell Caves (inf. Ian Standing). More recently, a small selection of

hammerstones have been recovered from the surface of old scowles within a quarry at Drybrook on the

east side of the Severn. Though fashioned from the same type of rock, at least one of these hammers

shows distinct evidence of grooving for hafting, whilst another appears to be a small crushing stone.

Small cup-marked hollows in bed rock near by (similar ones have been recorded from other sites in the

Forest) have also been interpreted as anvils/mortars for crushing hematite (Strassburger 2000 unpub).

No date has been ascribed to these workings, but it is has been suggested by Strassburger that they are

Bronze Age – [Drybrook – Gloucester SMR 20829]

Exmoor

At Roman Lode near Simonsbath on Exmoor evidence of Early Bronze Age activity has been excavated,

in the form of a large hearth and a deposit containing anthropogenically smashed quartz. It is

associated with the surface outcrop of a hematite lode exploited in historical times for iron (Juleff &

Bray 2007). Though the excavators considered that this might have been a prospect for copper, another

possible explanation for this (if indeed it was metallic mineral extraction) would be as an exploration for

hematite ochre pigment.

Cumbria

Pickin (1990) mentions the discovery in the 1870s of ‘two polished stone celts of the usual sort’ found in

old hematite workings at Stainton, Barrow-in-Furness, Cumbria (Kendall 1893; Tweddell 1876). He

then questions whether this might refer to a ritual/burial deposit in a natural cavern or whether this is

evidence for associated mining, presumably for pigment. Little can be made of such a find now, yet

prehistoric interest in such a resource is what one might expect.

2.2.2 Roman

Alderley Edge

It is possible that the Roman mine of Pot Shaft at Engine Vein (Timberlake & Kidd 2005) was worked

for a blue pigment made from azurite nodules extracted from a mudstone horizon within the Engine

Vein Conglomerate, as well as malachite and azurite disseminated within the softer underlying Bunter

sandstones. Pot Shaft is described in greater detail within the sections below on Roman copper and lead

mining, yet probably the closest comparison with this working appears to be the Roman mine excavated

by the Bochum Mining Museum at Wallerfangen-Saar in Germany (Korlin 2010; Strassburger pers

comm). This mine was worked for azurite pigment (Egyptian Blue) sometime during 2nd-4th centuries

AD. The azurite here was extracted from a fairly similar geological horizon using much the same type of

shaft and level construction.

2.3 Copper

2.3.1 Bronze Age

South-West of England

Fieldwork carried out over the last 20 years (Sharpe 1997) has revealed nothing in the way of

conclusive evidence for prehistoric hard-rock metal mining or copper extraction within the important

South-West (Cornubian) orefield of Cornwall and Devon. Some circumstantial evidence for the use of

stone mining tools can be found in collections such as those of the Zennor Wayside Museum (Craddock

& Craddock 1996), yet the only example of mortar stones plus several unconvincing cobble stone tools

came from an undated tin/copper openwork surveyed at Wheal Coates Mine, St.Agnes (Budd & Gale

1994). With any of these finds it has not really been possible to distinguish these tools from those used

later for the crushing of tin ore. Penhallurick (1986) describes the find of a Middle Bronze Age palstave

within an old work at Godolphin Mine, yet the best evidence he provides of hard-rock mining seems to

be a mineral specimen of botryoidal goethite, probably dug from a lode, discovered with Middle Bronze

Age pottery at Tredarvah.

Attempts to provenance metal artefacts may have provided some firmer evidence for extraction (Budd et

al 2000). This work analyzed the lead isotopes and trace metal composition of a group of five Early

Bronze Age copper artefacts, the result it was claimed indicate unambiguously a source within an ore

body associated with the Cornubian granite batholith and perhaps, more specifically, the St. Austell

intrusion. Although the number of artefacts analyzed was limited, this data could be important if it

provides confirmation that copper was exploited in the South West at a date at the very beginning of

the Bronze Age. There are certainly traces of copper metallurgy in the form of local copper-alloy

metalworking surviving at Middle Bronze Age settlements such as Trethellan Farm, Newquay

(Nowakowski 1991), yet there is no evidence, here or anywhere, of primary smelting. Three copper

ingots of Late Bronze Age date from St. Michael’s Mount (Herring 2000) and Kenidjack (Tylecote 1967)

might imply local production. But just as interesting perhaps is the evidence for Late Bronze Age –

Early Iron Age copper, bronze and lead-silver metallurgy at Gussage All Saints and Hengistbury Head

in Dorset (Tylecote 1986). The source of the copper used at the latter site is likely to be somewhere in

the South-West.

Isle of Man

The Isle of Man, an island rich in Beaker and Early Bronze Age remains and one of the principal

stopping-off points for the earliest seafarers between Ireland and Britain, was also on the route along

which some of the first metallurgists travelled. We can see this in the evidence (though still undated)

for prehistoric prospection around the southern tip of the island, such as on the Langness peninsula,

where hammer stones associated with an area of copper mineralisation were found during fieldwalking

in 1999 (Doonan & Eley 2000),whilst to the west of here, similar tools made of basalt beach cobbles

were recovered from North Bradda Head in 1998 (Doonan & Hunt 1999) and from South Bradda Head

in 1987 (Pickin & Worthington 1989). Adjacent to the natural harbour of Port Erin, South Bradda forms

a prominent headland which faces west and looks out across the Irish Sea, the visibly copper-stained

cliffs here being associated with a rich lode containing chalcopyrite, secondary minerals and quartz.

This natural feature was described by Lamplugh in 1903 as being ‘amongst the most spectacular

displays of quartz veining in Europe’. The presence of the mineral here can still be seen far out to sea,

much as it would have been in antiquity as the Neolithic and Bronze Age peoples crossed in their plank

boats or curraghs from Ireland. The existence of this ‘metal route’ seems all the clearer when we

examine the Copper Age/Early Bronze Age metalwork from the island which shows affinities with both

Irish and early Welsh and Scottish (Migdale) axes, along with the mixing (or recycling) of Ross Island

metal with copper from other sources (Timberlake 2009a).

Alderley Edge, Cheshire

In 1874 what was then suggested to be a prehistoric mining landscape (now believed to be of Early

Bronze Age date) was uncovered during the course of modern mining activity at Brynlow (Brynlow Field

Opencast within 100m of SJ 855773). This was first recognized by Boyd-Dawkins (1875 & 1876) who

inspected the site on numerous occasions in the company of other leading archaeologists of the period.

The stone tools from here (now in the collections of the Manchester Museum) were later described by

Roeder (1901) and Roeder & Graves (1905). An oak shovel, witnessed by Sainter (1878) as having come

from one of these early mine pits, and subsequently re-discovered by Alan Garner, was radiocarbon

dated in 1994: OxA-4050: 3470 ±90 yrs BP or 1888-1677 yrs cal BC (Garner, Housley & Prag 1994).

Today the site of this discovery is filled and grassed-over but still identifiable.

Elsewhere on the Edge, mining sites of a similar type were examined by Roeder (1901) and Roeder &

Graves (1905), and then subsequently by Oliver Davies (1935), Carlon (1979), Warrington (1965; 1981)

and others. These included in particular the Engine Vein, but also a site at Dickens Wood and the nowinfilled opencast of The Hagg in Windmill Wood, where three slagged sherds of a crucible – illustrated in the Roeder mss – were found. Also, Mottram St.Andrew, approx 1km to the east, where Roeder &

Graves’ 1905 map indicates the approximate position of the hearth and the hammer stones find. Other

sites thought to be prehistoric in origin include Devil’s Grave at Stormy Point and near to West Mine,

where workings originally believed to be ‘Roman’ were found in 1858. More recently those surviving and

still recognizable sites, such as Pillar Mine (Dickens Wood) – with its three now seriously eroded

bisected pit workings, large cave-like entrance and eroding Bronze Age mine spoil – and the Engine

Vein opencast to the south – with prehistoric pit workings and the remains of an incipient prehistoric

opencut – were re-examined by Pickin (1990; and in Blick 1991), Gale (1989; 1993 & 1995), and finally

by Timberlake (Timberlake & Prag 2005).

Following the survey work carried out by the Alderley Edge Landscape Project in 1997, an archaeological excavation was undertaken of a previously undetected pitworking close to the south-west end of Engine Vein. This working, which seems only to have been a

prospection undertaken within the mineralised sandstone prior to the main pitting and opencasting on

the vein itself, can now be ascribed with some certainty to the period c.100-150 years just before or after

1900 BC (Timberlake & King in Timberlake & Prag 2005). Four Early Bronze Age radiocarbon dates

were obtained from these excavations, including the charcoal associated with the firesetting and mining

of this pit (Beta-115606 3550 ±70 yrs BP or 2035 – 1690 cal BC) and a date for its abandonment, which

seems to be consecutive with continued working on the vein. Within the last few years archaeological

evaluation work carried out at Stormy Point by the University of Manchester Archaeological Unit has

revealed further evidence for Early Bronze Age and perhaps also later prehistoric mining in the form of

at least two prospection pits, one of which was dated to 1690 – 1510 BC (Mottershead & Wright 2008).

However, the absence of open-area excavation here has made it difficult to interpret this site further.

The production of copper (and perhaps also small amounts of lead) during this 100-200 year period of

mining during the Early Bronze Age may not have exceeded 20 tons of hand-picked and cobbed (crushed

and dressed) ore. Given this relatively small amount it seems possible therefore that the copper was

smelted locally up on the Edge. Although the evidence for this has yet to be found, in 1901 Roeder does

refer to hearths at Engine Vein which may have been roasting beds. Reconstructions of a primitive

smelting operation involving the construction of small ephemeral bowl furnaces fired with

charcoal/wood were undertaken at Alderley Edge during September 1997 and July 1998 (Timberlake

2005c).

Ecton Copper Mine

Stone tools ‘used by the aboriginal miners’ and found within in the Duke of Devonshire’s copper mines

at Ecton near Leek in Staffordshire in the1850s were displayed in the Derbyshire antiquary Thomas

Bateman’s collection (now at Sheffield Museum). Hammerstones were also found redeposited on old tips

at Dutchman by Graham Guilbert in the 1990s. Following underground exploration in 1997, the end of

a primitive red deer antler pick was recovered from amongst rock collapsed in from surface workings

some 20-30m underground near the top of Dutchman or Stone Quarry Mine. This provided an Early

Bronze Age radiocarbon date (1880–1630 cal BC at 95% probability) suggesting the existence of a

second locality for Bronze Age copper mining in England (Barnatt &Thomas 1998; Pickin 1999; Guilbert

1994a; 1994b). The ore deposits here consisted of veins and pipe workings formed from a combination of

tight anticlinal folds and faults within Carboniferous Limestone containing chalcopyrite completely

oxidised to malachite at surface.

In 2008 the Early Mines Research Group undertook surface excavations at the site of an old opencast

and later shafts at Stone Quarry Mine (as part of a Peak District National Park project funded by

English Heritage). These revealed evidence for 17th-century AD mining and the backfill of an earlier

opencast but amongst the later mine spoil emptied out from below were some stone hammers and bone

tools, some of which were subsequently dated to the period 1800 – 1600 BC. At The Lumb, a few

hundred metres away close to the summit of Ecton Hill, a series of shallow horizontal cave-like

workings were investigated in 2009. The excavation of a hollow in front of one of these revealed a small

outcrop working on a bed of cupriferous dolomitic limestone. This horizon appeared to have been mined

in prehistory with bone and stone hammers, before being re-worked in the post-medieval period. Some

preserved lenses of early mine spoil containing in situ flakes of bone and antler were encountered

amongst this; this included the tip of a worked antler tool, which gave the following date: OxA-21507

3445 ± 28 1880–1680 cal BC (at 95% confidence). Since that time twelve bone tools (points and scrapers)

from The Lumb and Stone Quarry mines have been dated and the results of these dates have been

Bayesian modelled in an attempt to establish the period and sequence of working (Tables 1 and 2). It

seems probable from this that Stone Quarry was mined first (and perhaps for longer) in the Early

Bronze Age, followed by The Lumb, the latter perhaps as a prospection (this included one Middle

Bronze Age dated bone tool). The bone tools were mostly made from split cattle tibia (rather similar to

the tools found on the Great Orme, Llandudno), whilst the majority of the hammerstones were handheld, un-modified river cobbles collected from the bed of the River Manifold at the base of Ecton Hill. No traces of an accompanying mining camp, or for that matter, nearby traces of processing or smelting

were found.

2.3.2 Iron Age

Currently there is little site-based evidence for Iron Age copper mining in the British Isles. One very

likely site, but one for which we have no dating evidence from the mine itself, is Llanymynech Ogof (SJ

265 222). This Carboniferous Limestone hill straddles the border between England (Shropshire) and

Wales.

Reputed in the 19th century to have been a Roman mine on account of the find(s) of Roman coins and a

coin hoard buried within mining deads underground, this small, and now well surveyed and explored,

labyrinthine system of mine passages seems much more likely to be Iron Age or earlier in date. Antler

pick tools have been found underground (Adams 1970) and also a single round hammerstone within the

entrance passage (Timberlake 1996). Most important of all was the result of a palaeo-environmental

study; the coring of a peat basin within the Iron Age hillfort (which also encloses the site of the mine)

has revealed evidence for mining or smelting-related copper pollution, which corresponds in date with

the occupation of this site (Moore 1992). In 1981 excavation of a pipe trench through the hillfort

rampart revealed two metalworking (bowl) hearths and a pit associated with the crude working of

copper dating to the period 275 – 10 BC (Thorburn 1988), and further hearths were discovered in the

early 1990s (Musson et al 1993). More recently, an excavation at Downgay Lane, Four Crosses (within a

few kilometres of Llanymynech) uncovered a Middle Iron Age copper smelting site with 13 furnaces

with some of the earliest examples for the use of tuyeres in the UK (this is as yet unpublished). The

lead and zinc-rich copper from here provides a reasonable match with the malachite ore from or of

Llanymynech Ogof (Tim Young pers comm).

2.3.3 Roman

Alderley Edge: Pot Shaft

In March 1995 an early 4th-century AD coin hoard, consisting of 256 bronze coins contained within a

pot, was found in the top of an infilled and previously unknown shaft on Engine Vein (Nevell 1996).

Following this discovery the full excavation of this shaft was undertaken by the Derbyshire Caving

Club in conjunction with the Alderley Edge Landscape Project (Manchester Museum) in October 1997

(Timberlake & Kidd 2005). This work revealed a 12m-deep abandoned Roman shaft and cross-cut level

which connected to the open stope of Engine Vein (see Prag & Timberlake). The 2m x 2m square shaft is

large by Roman standards, yet the method of sinking this and of driving the 7m long level from its base

shows clear similarities with Roman workings recorded in Spain and elsewhere. Although the discovery

of a Roman shaft dating from the first half of the 1st century AD is unique to Britain, the style of coarse

pick-work upon the walls is reminiscent of that witnessed in the Roman Penlanwen Adit(s) at the

Dolaucothi gold mine in South Wales (Manning 1968).

At Engine Vein it is believed that the shaft was used as a means of laddered access into a slightly larger

series of underground workings excavated upon the vein itself. Another similar shaft, of which only two

corners and an edge remain, is to be found some 20m away from Pot Shaft on the southern side of the

main Engine Vein opencut at SJ 86057748. The latter appears to be associated with an inclined walkway cut through the rock, as well as with slots cut into the side of a rock ledge some metres back from

the shaft, for the purposes of fixing what could have been a primitive wooden windlass or capstan;

suggesting that this may have been a haulage shaft. Another 20-30m to the east of here, and preserved

within the north wall of the opencut are traces of what may be another shaft and a gallery, the latter

truncating the bisected hollows (pits) associated with the earlier Bronze Age workings.

Unfortunately, there is as yet no conclusive evidence that any of these other features described are

actually Roman in date. Nor is there any evidence for an adit level associated with the above workings,

nor of surface spreads of Roman mine spoil, nor any archaeological evidence for the foundations of

buildings or processing areas which one might presume to find associated. It seems possible therefore

that the Roman activity at Engine Vein never amounted to much; perhaps a small mine or trial dug to

properly sample this vein for copper (or for lead and silver), the tactic being to test the unexploited vein

lying beneath the earlier Bronze Age workings.

The range of radiocarbon dates obtained from the in situ timbers found within the base of Pot Shaft do

not preclude a pre-Conquest (Late Pre-Roman Iron Age ) date for the working, yet based upon the style

of mining, an early date seems less likely. In fact the date for the use of this wood could easily be Early

Roman (mid-1st century AD) if one assumes that the radiocarbon dated sample of the basal sawn oak

timber included the heartwood (Beta 115611: 2120 ±60 yrs BP [360-280 Cal BC or 250 – 12 Cal BC/AD]).

Unfortunately dendro-chronological dating undertaken on this wood proved unsuccessful, and no

Roman pottery or other artefacts were recovered from this working. Mining could have been carried out

here under military control, perhaps even by the XX Legion from their base at Chester (Timberlake &

Kidd 2005, 94), but in any event was probably only a short-lived affair, lasting little more than 20 years.

This shaft and level make up the most complete archaeologically excavated Roman mining (feature) in

England.

2.4 Tin

2.4.1 Bronze Age

Although it seems highly probable that alluvial tin (as pebbles-sand consisting of cassiterite) was being

exploited during the Bronze Age from the tin-rich areas of Cornwall and Devon, the only convincing

evidence that we have of local extraction in the Early Bronze Age is of 7 fragments of tin slag associated

with a dagger within the basal layer of turves of the Caerloggas I barrow at St.Austell – an inefficient

smelting of local tin carried out in the 16th century BC (Miles 1975; Salter 1997); and the excavated find

of cassiterite pebbles at the Bronze Age settlement of Trevisker. The latter seems quite typical of the

cassiterite of Goss Moor from which the alluvial tin found in the Lanherne Valley (which could be

extracted in prehistory) seems to be derived (Penhallurick 1997). Penhallurick (1986) mentions over 40

prehistoric artefacts recovered from later tin streaming activities, some of which he considers could be

objects left by Bronze Age tinners, since the very same tin gravels are more than likely to have been

worked again. He lists a number if tin streams around the margins (of the source) granites that he

considers may have been worked in prehistory. Foremost are those around St.Austell, in particular the

Pentewan Valley, St.Erth and Marazion, and Treloy in St.Columb Minor. A Late Bronze Age hut on

Dean Moor, Devon had hematite within its walls which had been separated out from tin ore collected for

smelting. More recently, slags have been retrieved from domestic sites at Goldherring and Killigrew (see

Tin Assessment) and the early results of yet to be published geo-chemical sampling have indicated

strong elevations of tin deposition in Dartmoor peat in the prehistoric period (Meharg 2011, 1-11).

2.4.2 Iron Age

It has been assumed from classical sources (reference to the Cassiterides (islands) and to Ictis by

Diodorus (Penhallurick 1986)) that tin was exploited in the South-West and traded with the Continent

by at least the Late Iron Age (Todd 1987) and it is likely that such activity dates from even earlier,

especially when the early presence of trading sites around the coast by at least the Late Bronze Age is

considered (places suggested for the site of Ictis include St.Michael’s Mount (4th-1st century AD) and Mt.

Batten, Plymouth (from c.500 BC). Excavations at Chun Castle showed that tin smelting was being

carried out here in the pre-Roman Iron Age (3rd-2nd century BC); probably an indication of local

exploitation of tin (Tylecote 1986). Other similar sites include Trevelgue and the Iron Age settlement of

St.Eval.

2.4.3 Roman

Tin exploitation from placer deposits certainly continued during the Roman period as suggested by the

assemblage of ingots recovered from Cornish sites such as that of Late Roman date from Trethurgy

(Quinnell, 2004) stamped with helmeted heads (Todd 1987). A group of plano-convex tin ingots found in

1991-2 from Bigbury Bay, South Devon (thought to be Late Roman (4th –5th century AD) in date on the

basis of accompanying amphorae) may relate to contemporary trade and a link with an early Dartmoor

tin industry (Fox 1996). The tin streaming at Pentewan, St Austell has likewise turned up Roman

artifacts, as has Treloy in St. Columb Minor, where a Roman tin bowl was discovered in 1826. However,

given the sheer focused intensity of placer tin exploitation in recent centuries, it is generally accepted as

unlikely that physical remains of prehistoric or Roman workings of this type survive. Recent

examination of Devon’s river sediments, away from the moorland, has provided radiocarbon dates

suggesting that wastes from tinworking processes on Dartmoor were being deposited in the rivers in

both the Roman and post-Roman periods (Thorndycraft et al 2004).

2.5 Gold (Cornwall)

2.5.1 Bronze Age

Penhallurick (1986) emphasizes the regular recovery by tinners (during the historic period) of small

amounts of gold from tin ground at Treloy and within the Carnon Valley. Whilst there seems to be

strong circumstantial evidence for prehistoric tin working in these valleys, this by itself would not be

sufficient evidence to suggest these sites as an English Bronze Age gold source. More interesting is the t that 90% of British Bronze Age goldwork contains small quantities of tin in parts per million; yet

samples of Irish, Welsh and Scottish native gold are either devoid or very low in tin (Taylor 1980).

Cornish gold has been shown by Penhallurick (1986) to contain between 25-50ppm tin, whilst analysis

of the two Early Bronze Age gold lunulae from Harlyn Bay, Padstow revealed concentrations of 50ppm

and 950ppm tin, and that from St.Juliot 650ppm tin. It seems possible therefore that gold was produced

as a byproduct of alluvial tinning from the Bronze Age onwards, perhaps in the Carnon Valley.

Some work is currently being undertaken on trace element composition of native gold and Bronze Age

gold artifacts in Ireland, with a view to identifying sources (Warner et al 2010), but very little is being

attempted in England or the rest of the UK. Because of the purity of alluvial gold (93% Au) trace

element studies as well as studies of stable isotope ratios may prove quite effective in provenancing.

2.6 Lead and Silver

2.6.1 Bronze Age

South-west England

Burgess and Northover (Tylecote 1986, 27, 30) suggest that lead was being intentionally added to tin

bronze during the Acton Park (Middle Bronze Age 1400-1300 BC) and Wilburton (Late Bronze Age

1000-900 BC) metalwork periods, presumably from British sources, though it was not until the advent

of systematic stable lead isotope analysis of bronze artifacts and ores (Rohl & Needham 1998) that a

possible match could be suggested between Wilburton metalwork and a lead source in the Mendips,

Somerset. Although this cannot be verified, or a specific site identified, this level of provenancing is at

least useful in establishing the origins of lead extraction.

Peak District

The discovery of a Late Bronze Age socketed axe made of lead at Mam Tor (Guilbert 1996) might

represent the very earliest exploitation of this metal in the Peak. A lead ‘torc-end’, as yet not fully

published, was found in a pit at the centre of a large round house, both with Early Iron Age C14 dates.

This was at Gardom’s Edge above Baslow on the Peak’s eastern gritstone moors, during extensive

excavations undertaken by the Peak District National Park Authority and Sheffield University in 1995-

2000 (Barnatt et al 2002; J Barnatt pers comm) Late Bronze Age axes from Britain containing up to 15-

21% lead are all thought to have an indigenous source (Northover 1980).

Shropshire

Bronze Age mining, including for lead, has also been argued for Llanymynech on the Welsh-Shropshire

border (CPAT SMR PRN 23399).

2.6.2 Iron Age

Mendips

Todd (1996; 2007) has suggested pre-Roman (Iron Age) mining of lead at Charterhouse-on-Mendip on

the basis of finds of a 3rd-century BC Greek coin, a denarius of Julius Caesar, plus Iron Age pottery from

excavation trenches sampling ‘Roman’ mining rakes (opencuts) on the edge of the Charterhouse Roman

fortlet undertaken in between 1993-5.

2.6.3 Roman

Lead was used to produce plumbing and water management systems, coffins, lead glass and spindle

weights. It was alloyed with tin to produce pewter, and lead compounds were a common adulterant in

wine and cosmetics. Numerous Roman pigs of lead have been found on routes leading from the orefields

towards ports from where lead was exported to other parts of the empire and a Roman shipwreck at

Ploumanac’h in Brittany yielded a cargo of British lead pigs from the 2nd to 4th century AD (L’Hour

1987).

Mendips

Roman mining can be confirmed at Charterhouse-on-Mendip following excavations by Todd (1996;

2007), whilst mining elsewhere in Mendip is suggested by finds of Roman lead smelting slag within a

Roman enclosure just east of Priddy, at Green Ore where a 4 ha area is covered by slag, lead fragments

and Roman pottery (Todd ibid), and most probably the large 100m long and c.10m deep opencut mining

rakes on Ubley Warren near Charterhouse. Evidence so far obtained suggests that the latter area,

though not archaeologically investigated, produced most of the Roman lead ingot finds in the Mendip.

Excavations from 1993 close to the Roman fortlet revealed evidence for mining during the period AD 50-

80, based on pottery finds (Todd 2007, 68).

The only excavations undertaken on the Mendips (by Todd at Charterhouse) suggest the possible

survival of in situ mining features and likely smelting hearths dating from the early Roman period.

Also, possible pre-Roman remains dating from the 1st millennium BC. Potentially one of the most

important early Roman lead mining areas within Britain, this area is worthy of detailed survey, soil

augering, geophysics and a better planned and larger scale excavation. Given the silver content of these

ores, the Mendip is also an area to look for evidence of silver-extraction (cupellation) from these ores

(see Ashworth 1970, 15).

Combe Martin

Combe Martin is known to have been a source of lead and silver from at least the medieval period, but

recently this location has yielded finds of Roman pottery and a stylus from beneath a considerable

depth of deposits at least partially derived from mining (T Dunkerly pers comm). Such evidence, slim

though it is, may be indicative of Roman working.

Calstock

Excavation of the recently discovered Roman fort at Calstock (a medieval silver mining/ smelting

centre) revealed a layer of mineral vein spoil within the Roman ditch and a Roman furnace which it was

suggested may be associated with smelting. Analyses are awaited.

Alderley Edge

It is distinctly possible that the substantial, but somewhat sandy or silicic, lead vein at Engine Vein

was the goal of the Roman miners when sinking Pot Shaft (Timberlake & Kidd 2005). There would have

been a significant demand for lead as pans for use in the Roman salt industry, centred around

Nantwich and Middlewich (Cheshire).

Peak District

No direct evidence of Roman mining is forthcoming, though numerous finds of lead pigs (cf

LUTUDARUM) would seem to suggest some local production, presumably by private concessionaires

rather than under military control. The Matlock area has been suggested as a location for this activity

(Tyler 1982); possibly mining was organized here by the mid-late 1st century AD (Boon 1971). A trench

dug to investigate a 2nd-century AD field wall at Roystone Grange located a small buried ‘scrin’ or

opencast (Barnatt & Rieuwerts 1998), though a more recent reevaluation of this has brought the Roman

dating of this boundary into question (Barnatt 1999). No Roman bole smelting hearths have been

identified within the mining areas, though a lead smelting hearth associated with a Late Roman villa

has been identified at Scarcliffe Park near Duffield on the Nottinghamshire-Derbyshire border (Willies

1982; Craddock 1995).

Excavation and dating of some of the numerous lead bole sites in the Peaks may be an easier way to

help identify the probable locations of Roman and Early medieval mining and could reveal how closely

these are related.

Shropshire

During working of the Roman Gravels Mine (Shelve district) in the 19th century, Roman coins, tools

(wooden shovels) and considerable traces of stepped opencast workings linked to underground galleries

and shafts were found and described (Wright 1862; Tyler 1982). The ‘find’ of a pig recorded at Roman

Gravels is unlikely to be genuine; it occurred about the same time as the ‘Roman’ was added to the

mine’s name and has the hallmark of a way of creating interest in shares in the mine. At least three

Roman lead pigs have been found in Shropshire which are accepted as being of local lead and there

have been other pigs found out of the county which could have been produced in Shropshire. Openworks

are still accessible at Roman Gravels, if overgrown, and as yet they are undated (Shaw 2009, 13).

Roman and earlier mining in Shropshire has also been researched by White (2000). The cupellation of

silver was practiced on the Shropshire / Welsh border at Pentrehyling (Bayley & Eckstein 1998).

County Durham

The only field evidence for Roman period lead mining in County Durham is circumstantial, in the form

of artefact finds from Slitt Mine, Westgate. A hoard of nine silver denarii of Vespasian, Antoninus Pius,

Hadrian, Faustina I, Marcus Aurelius, Lucilla and Trajan (date range AD 98-141) were apparently

found on edge of open work on the Slitt Vein (described as ‘near the quarry workings’). The description

of the find spot is open to interpretation (hoard deposited in abandoned working, mine contemporary

with hoard or hoard in secondary context and displaced by later mining?) and would benefit from reexamination. A hoard with a similar date range was discovered in the same general area at High Westgate in the 1870s. Slitt Vein is the longest and one of the strongest lead veins in Weardale and

outcrops at surface along much of its length. At Slitt Mine the vein is cut and exposed by the valley of

the Middlehope burn, so a good location for early prospection/mining (Archaeologia Aeliana 1925, 24;

Burnett et al 1986)

The Roman economy of the South Pennines has been thoroughly explored by Dearne, who focussed in

particular on the lead industry (Dearne, 1990).

Alston, Cumbria

Mining here, it is claimed, was carried out by the second cohort of Nervians during the 3rd century AD

(Webster 1952). Whatever the nature of this evidence, the recent excavation of a lead smelting furnace

within the industrial zone adjacent to Carlisle Roman Fort is probably linked, in some way, to lead from

the Alston orefield (Murphy & Zant forthcoming).

2.7 Zinc

2.7.1 Roman

Mendips

No evidence of this survives in the UK, but given the mining of lead from these veins, it seems possible

that the abundant near-surface calamine (smithsonite or zinc carbonate) ores were exploited by the

Romans for the purposes of making brass using the cementation method (deposits at East Harptree

etc).

2.8 Iron

2.8.1 Iron Age

In the archaeological record the evidence for iron extraction is chiefly to be found in the remains of

smelting hearths, the original sources of ore being identified on the basis of ore samples found with the

hearths. Here we see a development in Britain from the bowl furnace to shaft furnace to slag pit furnace

(Tylecote 1986). The occurrence of iron smelting at sites away from known sources of iron ore (e.g.

Mucking in Essex, Hevingham in Norfolk) attests either to the movement of ore or else to the once fairly

universal occurrence of bog iron. Geological sources of iron ore are also fairly widespread: from vein

hematite and goethite (Furness in Cumbria; Brendon Hills, Somerset; Forest of Dean), to blackband

(siderite) ironstones ubiquitous within the coalfield areas of Britain, Wealden ironstones (siderite) from

Sussex, Hampshire and Surrey, and the Cretaceous Greensand (Carstone of Bedfordshire etc and Upper

Greensand ores of Devon).

Dorset

At Hengistbury Head locally collected iron ore was extracted from outcrops in the cliffs and smelted

between 400BC and AD 50 (Bushe-Foxe 1915). Similar evidence for locally sourced iron ore and

smelting comes from Gussage All Saints (Wainwright et al 1979).

Wiltshire Iron ore was smelted at All Cannings Cross, Wiltshire. between 400-250 BC using ore from the local

Lower Greensand , probably from Seend (Cunnington 1923)

Somerset

A second short rake (opencut) at Charterhouse-on-Mendip examined by Todd in 1996 proved to be for

hematite, rather than for lead, and from which a denarii of Julius Caesar (48 BC) plus some Iron Age

pottery was recovered. Elsewhere, other potential Iron Age mineworkings are poorly explored and often

undated; these include potential sites at Kitnor Heath on Exmoor and Colton Pits in the Brendon Hills

(L Bray pers comm)

Devon

An Early Iron Age smelting site at Kestor near Chagford in Devon can be dated to just after 400 BC.

The bellows-blown hearth may well have been reducing a local bog iron ore (Tylecote 1986). [PN note:-

Peter Crew has now got a C14 date from charcoal embedded in the iron slag at Kestor, and this is

broadly 6th century AD. Peter also says that the slag at Kestor is typical of trial working of ores that

didn’t quite work out, not part of a regular if small scale production process – not sure if this is the

main Kestor site (above) or the more recent hut circle excavated by Sandy Gerrard. Perhaps Peter has

more details OK]

Cornwall

One of the earliest iron extraction sites in this county is at the promontory fort of Trevelgue Head

where, within the Mid and Late Iron Age, between 1.5 and 2.3 tonnes of iron were produced. This is

likely to have been extracted from a narrow lode running through the headland on which the site is

located (see Dungworth in Nowakowski 2011). The low level of iron production is notable on this site,

which amounts to between 10 and 20 kg of iron, or 2 to 3 smelts each year. This suggests that the scale

of Iron Age extraction was limited and that we are unlikely to identify sites of this type unless they

were exploited for significant periods.

Surrey

The site of Brooklands near Weybridge produced up to 44kg of slag as part of the waste from slagtapping furnace(s) operated between the Early – Late Iron Age (from the 5th century BC to 1st century AD), the source of the ore used probably being high-quality sideritic ironstone outcropping at the nearby

St.George’s Hill (Hanworth & Tomalin 1977). At Purberry Shot near Ewell, furnace bases and a bloom

dating from 200 BC – AD 150 represent a small industry using local iron ores from the Wadhurst Clay

(Lowther 1946).

Sussex

Pre-Roman iron smelting (190-80 BC) in shaft furnaces with slag-tapping pits has been identified at

Broadfield near Crawley in Sussex (Gibson-Hill 1980), the latter using local Wealden iron ores

(siderite). As well as smelting, local Wealden Iron Age bloomery sites have been investigated, such as at

Crowhurst Park, Bardown and Chitcomb (Tylecote 1986).

East Anglia

Iron smelting as well as ironworking has been encountered at recently excavated fenland edge Iron Age

settlements such as at Bradley Fen, Cambridgeshire (Gibson & Knight forthcoming), the latter possibly

exploiting local bog iron ores, or else Northamptonshire ironstone, which may have been sourced from

the southern part of the East Midlands orefield (Fincham 2004).

Northamptonshire

Associated with the settlement at Hunsbury (Fell 1936) were pits containing a significant amount of

iron slag suggesting smelting operations using the local Northamptonshire ironstone. Other Iron Age

furnaces have been found at Wakerley (Tylecote 1986).

Perhaps one of the most interesting case studies relates to excavations in 2006 by Archaeological

Project Services of some seven slag-tapping furnaces found during investigations adjacent to a Roman

villa at Priors Hall, Corby (British Archaeology Feb. 2008). Later Iron Age pottery (100 BC – AD 43) and

tuyere fragments were recovered – perhaps the best preserved examples of furnaces complete with

tapping arches and pits and the furnace superstructure from this Late Iron Age period. The local

Northamptonshire ironstone is likely to have been smelted, most probably from outcrops within the

area of Rockingham Forest.

East Yorkshire

The spectacular Middle Iron Age ‘Arras Culture’ linked to important chariot burials and the excavation

of the Hasholme log boat was home to one of Britain’s largest prehistoric iron industries dating from

around 300 BC. The iron industry appears to be based on large deposits of bog iron ore within the

coastal Foulness Valley south of Holme, Humberside4 Furnaces and large quantities of iron slag from

the smelting of these sandy bog iron ores have been excavated at Whelham Bridge, Yorkshire (Halkon

& Millet 1999).

Northern England

Early Iron Age (7th-6th century BC) furnaces have been found at West Brandon in Durham (Jobey 1962),

and at Roxby in Cleveland (Spratt & Inman 1986), the latter exploiting the local Cleveland iron ore.

2.8.2 Roman

Cornwall

Restormel Roman Fort is located close to an important iron vein (Restormel iron lode).

Blackdown Hills, Devon

A landscape of early iron extraction pits can be seen within areas of the Blackdown Hills.6 Most of this

extraction is undated, but trial archaeological excavations associated with a large-scale survey of the

deposits identified smelting sites dating to the Saxon period but also to the Roman period, the latter at

Hemyock near Upottery on the River Otter north of Honiton. Pottery from these layers produced a date

in the second half of the 1st century AD (AD 50-70), a date which suggests Roman military control or an

overview of exploitation centered perhaps on the legionary fortress at Exeter (Griffith & Weddell 1996).

Iron ore, geologically similar to that from the Blackdowns, was recovered during excavation of the

Roman fort at Bolham, Devon (Maxfield, 1991).

Exmoor

Iron production grew from the beginning of the 2nd century AD reaching substantial levels on sites on

the southern fringes of Exmoor such as Sherracombe Ford and Brayford. More recently a Late Roman

smelting site has been identified at Blacklake Wood as part of the Exmoor Iron Project (ExFe) under the

leadership of Gill Juleff at the University of Exeter. Sites have been identified through geophysics

(magnetometer and magnetic susceptibility), geochemical (PXRF) survey (Carey 2005), and then

archaeologically excavated and dated (Bray 2002). A number of complementary scientific approaches

have also been tried in this area (Dean 2003; Brown et al 2009; Fyfe 2003; 2009; Karloukovski, &

Hounslow 2006). The suggested source of much of the Roman iron smelting seen in this area is ‘Roman

Lode’ at Burcombe near Simonsbath. The anciently worked lode (goethite) is over 600m long and is

opencasted to a depth of over 5m. (Fletcher et al 1997). Excavations at this site have been carried out

by Bray (2002; 2006).

Somerset

At Treborough and Luxborough there is evidence of Roman extraction of iron ore at outcrop (Yates

1858). Roman exploitation of the hematite ores of the Brendon Hills has been suggested at Colton Pits,

though there is no datable evidence (L Bray pers comm) and at Clatworthy Reservoir, samian pottery

scatters have been found in the vicinity of bloomery slag heaps.

Gloucestershire

At Lydney (Wheeler 1932) a small underground working of iron ore (goethite) was located, the latter

working a band of ferruginous marl, and later sealed by a 3rd century AD hut (see also Scott-Garrett

1959).

Forest of Dean

Ancient opencast workings known as scowles are relatively commonplace in the Forest. These represent

surface worked-out portions of iron veins and also solution-filled (iron ore) cavities within the limestone.

In some cases these can be traced for several kilometers and represent massive iron ore extractions.

Almost all are undated, but given the examples of pottery and coins unearthed (as at ancient iron

smelting sites near Whitchurch and mining and smelting sites at Tidenham, Coppet Wood Hill, Perry

Grove and Crabtree Hill) and the nearby Roman iron-smelting settlement of Ariconium, it is more than

likely that some of these at least are Romano-British in origin (Nicholls 1866). Finds from some of the

other sites suggest Early Medieval working (Nicholls ibid.). The classic scowle workings at Puzzle Wood

near Coleford are thought likely to be Romano-British (Blick 1991). A general summary of the topic has

been attempted by Wildgoose (1993).

From the 3rd century a reduction in the size of iron production sites is apparent in Britain and the a

concomitant decrease in the scale of extraction can be expected although no workings are currently

known from this date. The exception to this is the Forest of Dean where iron production increased

during Later Roman period.

Northamptonshire

The fact that large numbers of smithing furnaces were found at Corstopitum (Roman Corbridge),

though little evidence of smelting in the form of slag, might suggest that the Roman military did not

bother to smelt iron themselves, but instead relied on British smelters (Tylecote 1986). However, there

is evidence of domestic smelting of iron within this iron-producing region of the Midlands, particularly

in 2nd –3rd century villas such as Great Weldon (British Archaeology Feb 2008). The Northamptonshire

ironstone was worked from shallow surface outcrops by means of opencasts. Smelting furnaces at Kings

Cliff near Bulwick lie close to possible workings (Jackson 1979, 31-7). Traces of these workings within

the Northamptonshire orefield have been found at Oundle and Laxton (Taylor and Collingwood 1926).

Lincolnshire

Roman iron smelting remains have been found at Pickworth, Bagmoor, Costerworth and Thealby, and

at Claxby these smelting locations lie within the area of iron mining and outcrops of the Northants

ironstone (Cooper Key 1896).

Norfolk

At Ashwicken nodular iron ore was obtained by extraction pits over a horizon within the Lower

Greensand (carstone) some 3m – 13m deep (Tylecote 1967). These minepit workings cut through

Boulder Clay down to the Lower Greensand, the clay being used in the construction of tree-trunk patten

moulded furnaces for immediately local smelting. The latter formed some of the best shaft smelting

furnaces seen in Roman Britain (date 2nd century AD). Large slag cakes found at Hevingham, North

Norfolk also suggest local smelting.

Sussex

Wealden iron ore (nodular siderite and occasionally limonite) was extracted by means of pits. These

were noted at Minepit Wood in Sussex associated with smelting furnaces (possibly a bowl furnace type)

dating from the 1st-2nd century AD (Money 1974). The furnaces were charged with a mixture of siderite

and oak charcoal – the siderite came from the Wadhurst Clay exposed within the immediate vicinity.

Other Wealden Roman furnaces have been found within the same area at Cow Park and Pippingford,

Hartfield, and also at Holbeanwood and Broadfield near Crawley (Cleere 1970 and Tebbut and Cleere

1973). RB iron production in the Weald has been reviewed by Hodgkinson (1999).

Recent archaeological excavations and also reconstructions of Roman iron smelting furnaces have been

undertaken and recorded by the Wealden Iron Research Group (WIRG) founded by Cleere and Crossley

in 1968.

Northern England

Both ore and slag are associated with smelting remains at the Roman fort of Templebrough near

Rotherham, Yorkshire, whilst the fort of Galava at Ambleside produced evidence of the smelting of local

bog iron ores (Tylecote 1986).

2.9 Fossil fuels

2.9.1 Coal

Iron Age

Evidence for the very early (7th-6th century BC) use of coal as fuel in iron smithing operation comes from

the palisaded site of Huckhoe in Northumberland (Smith 1905). Associated with a large quantity of coal

within the hearth was a piece of part-welded iron. It is not known from where the coal came, though

local surface outcrops abound nearby. This example seems to be unique for prehistoric Britain.

Roman

There is evidence for the use of coal in a military context for domestic heating and perhaps also iron

smithing, within the northern forts on the Antonine and Hadrian’s wall (with possible sources as

outcrop workings in the Northumbrian and Midlothian coalfields). In particular, the use of coal is

reported in the archaeological literature at Housesteads and Corbridge fort(s), as well as at Chester and

Manchester (Preece & Ellis 1981). Contemporary documentary record also suggests the use of coal to

maintain the perpetual fire at the Temple of Minerva in Bath (Aquae Sulis). It would seem that there

was one cluster of coal use in Roman Britain within the Flint-Chester area (perhaps with a source in

the North Wales coalfield), and another in the area of the Bristol Channel area and then south east as

far as Silbury Hill (source in the South Wales and Bristol and Somerset coalfields). The final cluster is

to be found in East Anglia between Cambridge and the Wash.

These sites lie 200 miles by sea and 40 miles by land from the nearest coalfield sources. The distribution of sites might relate to their proximity

to the Roman Car Dyke from The Wash to near Cambridge. Coal may have been brought by sea from

Yorkshire or Northumberland, much as in the same way sea coal was extracted and then brought by

sea and canal to Cambridge and the other East Anglian towns (Preece & Ellis 1981, 17). Small

quantities of coal were found at Roman Wroxeter and Meole Brace, both in Shropshire, though whether

the coal was from what was to become the Shrewsbury coalfields or from the Coalbrookdale area cannot

be established, but in each case coal was later mined in the vicinity(Ellis 2000; Evans 1999).

In the most recent study of Roman coal, Travis has provided a persuasive argument for coal mining to

have taken place in many areas of Britain in the Romano-British period based on secondary finds and

coal residues retrieved from a number of non-mining sites, confirming extensive coal usage. He was also

able to provenance some samples of coal taken from Roman contexts to specific seams. However, the

work was unsuccessful in identifying the site of a single Roman coal mine, such is the elusiveness of the

evidence (Travis 2008).

The only putative Roman coal extraction site listed in the EH Coal Industry MPP Assessment (Gould &

Cranstone 1993) is Stratton Common near Stratton on the Fosse, Ashwick (Avon). Apparently anciently

worked coal outcrops here provide the nearest source of coal to Roman Bath on the Roman road network

(the worked area straddles the main road to Bath). Documented mining began here in 1300 AD, but it

seems likely that the mine had much earlier origins (Down & Warrington 1971, 224-6).

2.9.2 Oil Shale

There is evidence for this (Kimmeridge Shale) being used as a fuel in Iron Age salt production (boiling

and evaporation of brine in briquetage pans) at Kimmeridge in Dorset (D Cranstone pers comm)

2.9.3 Peat

Roman salterns (salt working sites) within Essex, Cambridgeshire, Norfolk and Lincolnshire may have

used peat as a fuel for boiling and evaporating brine within briquetage pans (Lane & Morris 2001).

2.9.4 Jet

In effect almost all true jet used in Britain from the Bronze Age to the Roman Period originated in the

Whitby coastline of North Yorkshire. Much of this jet may originally have been sea-washed pieces

eroded out of the Upper Lias (Lower Jurassic) shales (specifically the thin Upper and Lower Jet Beds)

which make up part of the strata of these cliffs. Bead production could have been assisted by mining the

thinnest laminae of jet fresh from the shales themselves. Extractive sites of this period have not yet

been identified.

Prehistoric

Jet is an important grave good (as jet buttons or necklaces of small beads and spacers) accompanying

inhumation burials within Early Bronze Age barrows. X-Ray Fluorescence analysis of all 117 pieces of

the Kill y Kiaran necklace found with this barrow burial in Scotland suggest that all but 24 of these

beads were made of Whitby jet.

It seems possible that the remaining ones could have been of cannel coal – a similarly indurated form of

mineral coal which does nevertheless have an inferior lustre. Cannel coal was sometimes used for

making bracelets and beads. Sources for this includes the Lias of the Dorset coast.

Roman

Jet was used in a similar fashion to prehistoric burials; in this case female individuals were

accompanied by jet jewellery in the case of inhumation and sometimes coffined burials of rich

individuals. The products of the industry have been researched and provenance of some Roman finds

assigned to the Whitby area, with a possible specialist centre at South Sheilds (Allason Jones & Jones

1994; Allason Jones 2002). Extractive sites of this period are yet to be identified.

2.9.5 Amber

Prehistoric and Roman

Sources of amber used in prehistory as jewellery (within Early Bronze Age burials) are almost certainly

from beach collection along the east coast of Britain; East Anglia (Suffolk) being amongst the most

common. The original source for this is likely to be the Baltic – the fossil resin being washed out,

floating across the North Sea.

2.10 Flint

The use of flint for tools and other artefacts, (excluding gunflint) is largely restricted to the prehistoric

period. Burnt flint is associated with burnt flint mounds, and is used as a temper in pottery, yet its

main specific use is as worked flint tools, either as flakes (blades and scrapers) or else as core tools such

as axes. Within the Neolithic these axes were traded, either as rough-outs or else as polished examples.

Opportunistic surface collection in the Mesolithic gave way to the shaft-mining from

unweathered/unflawed floorstone flint within the Upper Chalk during the Neolithic. In the latter

period, mined flint accounted for a small proportion of the total consumption of the material; the

majority was retrieved from natural surface deposits or from chalk cliffs. Some academics now believe

tools fabricated from the best mined flint may have had a ceremonial function beyond any practical

purpose (Barber et al 1999).

Prehistoric flint mining has received a good deal of attention from early researchers including Clark

(1911) but more recently general studies have been published by Holgate (1995) and Russell (2001a). A

national survey of the landscape evidence for flint mining sites in England by the RCHME, entitled

‘Industry and Enclosure in the Neolithic’ culminated in a monograph (Barber et al 1999).

2.10.1 Prehistoric

Salisbury Plain

The South West did not see intensive flint extraction in the form of mining, except in Wiltshire where at

Easton Down a complex of more than 200 shafts dating to Neolithic has been recorded, though with

associated Beaker settlement (Wiltshire HER No. SU 23NW 101). It was probably an outlier from

mining further east. Other sites within 10 miles of this include Durrington and Martin’s Clump, the

latter site in Hampshire. Martin’s Clump seems to have been an earlier site (4200 – 3700 BC) whilst

Easton Down has dates from around the end of this period to around 2700 BC (Barber et al 1999). Chert

resources were also exploited, but both flint and chert appear to have been exploited in a more

opportunistic, less organized, way than further east (inf L Bray).

South Downs

The largest and perhaps earliest group of Neolithic flint mines is to be found within the Upper Chalk

landscape of the South Downs in West Sussex. This forms a line of sites along the downland ridge from

Nore Down in the west to Cissbury in the east (Nore Down, Stoke Down, Long Down, Harrow Hill,

Blackpatch, Church Hill/ Tolmere Pond, and Cissbury). This area was the subject of aerial

reconnaissance in the 1990s (Barber & Dyer 2005). Probably the earliest mines (forming a landscape of

single shafts and upcast loosely following the contours of the hills) are those of Church Hill and Harrow

Hill spanning just over a millennium of the Early Neolithic from 4500 to 3400 BC, contemporary with

the construction of the causewayed enclosures.

These mines were first excavated by the Curwens in the 1920s (Curwen, E & E C 1926) and more recently by McNab (1996). The site was re-surveyed by the

RCHME in 1998 (Oswald 1998; Barber 1999). The important site of Cissbury (near Worthing) appears

later, commencing around 4000 BC and ending around 2900 BC, the latter date just contemporary with

the beginnings of Stonehenge and the earliest Beakers. Cissbury, which is disturbed by later hillfort

construction (Field 1994, 22-5), was first excavated by Colonel Lane Fox in 1875, whilst Cissbury,

Blackpatch, Church Hill and Harrow Hill were later investigated underground (between 1922 and

1955) by John Pull, whose work has been summarised recently by Russell (2001b). At Cissbury, flint

workings included small circular or sub-circular pits, large single shafts and large paired shafts linked

by a common spoil tip. Traces of ladder, antler picks, hand held hammerstones, pottery and pictograms

on the walls of the galleries were noted. Surface quarries first exploited the outcropping flint seams,

which was then followed upslope by increasingly deeper shafts – the lower workings becoming buried

beneath the spoil of the later shafts. The product of these mines were generally rough-outs of flint axes,

many of which it appears (from the evidence of knapping debitage) were knocked up on site.

Norfolk

Two other underground Neolithic flint mines, Buckenham Toft and Grime’s Graves, form a small group

(the Breckland Group) within the Brandon area of Norfolk. Canon Greenwell first worked at Grime’s

Graves between 1868 and 1870. It was this work excavating the shafts and galleries which prompted

excavations at similar sites in Sussex. The method of Neolithic mining here was to excavate galleries

above the preferred floorstone layer, after first excavating down through the other seams, the large flint

nodules being prised up from the floor with antler picks. Early 20th-century excavations at this site were

published by Clarke (1914), Armstrong in the 1920-30s, and by Mercer and Sieveking in the 1970s

(British Museum). It seems likely that this largest group of Neolithic flint mines (of more than a

hundred shafts) is a later phenomenon, only just overlapping with the mining at Cissbury (3000 BC)

and finishing after 2000 BC, thus spanning the period of Stonehenge. A range of workings from

prospection pits to opencast workings, to pits, to single to double (paired) shafts can be identified. The

product, at this late date, does not appear to be (polished) flint axes, but possibly quality flint for

smaller tools (Craddock et al 1983). Grime’s Graves is an English Heritage protected guardianship site

and has been the focus for much recent archaeological research including excavations published by

Mercer (1981) and Longworth (1986) plus a large number of specialist fascicules associated with these

works (see also Section 11.3).

Hampshire

A flint mine at Over Wallop was first reported by Stone (1933, 177-80) but much later Ride (1989, 213-

5) suggested that the excavation from a single shaft here has parallels with the Easton Down Mines

Surrey

Two flint mine shafts about 12ft deep, one Neolithic, the other medieval were excavated at East Horsley

in 1949. Two working floors were found associated with the Neolithic mine with finds including a

Campigny type axe, 80 implements, 715 wasters, pot boilers, chalk balls and Neolithic ‘A’ pottery. A

Thames pick was also found (inf. Surrey HER 2040; 2643. See also Todd 1950; Wood 1951).

Essex

A flint mine near Grimsditch Wood was listed by Morris in the 1920s, but no further information is

available (Morris 1923, 63-4).

Other flint

Surface extraction of flint in the Neolithic and Bronze Age for artefact production is much more

widespread – extraction sites are common on the edges of the chalk outcrop on the North and South

Downs, the Chilterns, and the chalk of Cambridgeshire, Suffolk and Norfolk – often associated with

Clay with Flints deposits and with flint-filled solution hollows and periglacial features.

The earliest Lower Palaeolithic flint tools (and thus extraction/collection of flint) has recently been

identified and dated (to 800 000 years BP) within interglacial deposits at Happisburgh on the North

Norfolk coast (Parfitt 2006). At Boxgrove near Chichester, at a hunting and butchering site associated

with a raised beach, flint (core) tools dating to 500 000 years BP have been found (Parfitt ibid).

2.11 Polished stone axes

South West England – Cornwall

One of the most significant uses of stone in prehistory was for the production of polished stone axes in

the early Neolithic. These have a widespread distribution within Britain and can be divided, based on

their lithology, into groups, a number of which originate within the South West Peninsula. Mercer

(1986), for example identified nine outcrops in Cornwall that were the sources for the majority of the

polished axe assemblage from southern England. The suggestion is that rock types from the South

West, especially Cornwall, had cultural significance. The Neolithic settlement of Carn Brea, Camborne

produced 18 polished axes made of Group XVI rock (an epidiorite or greenstone), the source for which

has been identified nearby at Camborne (as yet no actual extraction sites have been identified). Other

Cornish axe sources include the greenstones represented by Groups I (a uralitized gabbro from Mount’s

Bay area, Penzance), IV (an altered picrite from near Callington), and XVII (an epidiorite from

St.Austell) (Davis et al in McK Clough & Cummins 1988).

Lake District and Northern England

Perhaps the best known of stone axe quarry site(s) in Britain are the prolific factories to be found in the

Great Langdale and Scafell areas of the central Lake District (Cumbria). These have been well studied

since the mid-20th century, including work by Plint (1962;1978), Claris et al (1989), Houlder (1979) and

Edmonds (2004). The sought-after rock is an epidotized intermediate tuff of the Borrowdale Volcanic

Series : Group VI of the British stone implement petrology groups (Keiller, Piggott & Wallis 1941). This

stone was quarried at outcrop throughout the Later Neolithic, using hammerstones and occasionally

fire; the debris from the quarrying and initial shaping of axe blanks littering the slopes below these

outcrops, for example the scree below Stickle Pike. Early investigations of this site were undertaken by

Bunch and Fell (1949), but more recently work has been undertaken by Oxford Archaeology North

(Anon 2000). The resulting polished axes from this production account for over 20% of all published

stone implement identifications, their distribution being very widespread across Britain, with some

spread of artefacts into Europe.

Other polished stone implements from Cumbria include the axe-hammers and other perforated

implements fabricated from micaceous sub-greywackes (Group XV), the latter rock originating within

the Southern Lakes, but perhaps not at quarry sites. Perforated implements of quartz dolerite have also

been identified from the Whin Sill of Northern England (Group XVIII), whilst locally distributed axes of

a sedimentary rock consisting of carbonate mudstone (Group XXVI) can be linked to the Lias of North

Yorkshire.

Midlands

Axes and perforated stone implements made of an epidotized ashy grit (Group XX) can be linked to

Precambrian rock outcrops at Charnwood Forest in Leicestershire, as was the distinctive igneous rock

camptonite (Group XIV) outcropping near Nuneaton in Warwickshire.

2.12 Building Stone (see also Section 3)

Quarry site information has been obtained from the MPP Quarrying Industry Step 3 Report produced

by the Lancaster University Archaeological Group (1999). Other information has come from

archaeological grey reports; sometimes there is information on well-known geologically and

geographically localised stone for which no known (contemporary) quarry site(s) are known.

2.12.1 Prehistoric

South-East England

Stone (Binstead Stone) from Iron Age sites in Southern England has been petrologically sourced to

quarries at Binstead on the Isle of Wight.

2.12.2 Roman

South-East England

Barnack Limestone (oolite)was quarried for faced building stone at Barnack Holes and Hills in North

Cambridgeshire. Other building material used in Roman buildings in East Anglia, Lincolnshire and the

Midlands includes Ketton Stone and Collyweston Slate (as a roofing slate or floor tile); quarried in

Ketton and Collyweston in Southern Lincolnshire. Clunch (Totternhoe or Burwell Stone) from the

Lower Chalk may also have been quarried as early as the Roman period at Reach or Burwell in

Cambridgeshire.

South-West England

South West England contains a wealth of different types of building stone, from the limestones of the

east to the granites and slates of the west. However, the use of stone for construction is predominantly a

Roman period phenomenon and even then is generally associated with a significant degree of Roman

cultural influence. For the most part local stone was used for construction; the cost of transporting

stone over any distance mitigating against long distance shipping in most cases. Consequently, many

quarries of this date are of small size and perhaps not exploited for long periods after the immediate

demand for stone was over.

However, occasionally the characteristics of specific types of stone made them particularly suitable for some uses and quarries might be exploited for longer periods. An example is Beacon Hill near Shepton Mallet (Somerset HER UID 15485), a source of Devonian sandstones where

extensive remains of quarrying in the form of bell-shaped pits and vertical rock faces have been

identified. The demand for such types of stone could overcome the economic constraints on transport.

This was the case with the slates of South Devon which were exploited in the later Roman period to

supply roofing material for Exeter (Holbrook & Bidwell 1991). In this case the stone could be

transported by sea, the volume of such traffic being sufficiently great that it appears to have provided

the infrastructure to enable production and distribution of local pottery to expand significantly.

Similarly, the exploitation of the limestones of the region appears to have been important. These

included Bath stone, the oolitic limestone of the Cotswolds, and Purbeck stone, the latter being

transported significant distances for use in inscriptions. Although the products of such activity are

widespread (see Blagg (2002) for example) and its economic significance must have been high, little is

known about the archaeology of the extraction of building stone in this period in the South West.

In Avon at Dundry Down there are Roman stone quarries. Limestone (Beer Limestone Quarries)

showing evidence of Roman working (in the form of an early adit) survive near Beer on the South-East

Devon coast. Meanwhile, at Lady Down, Tisbury in Wiltshire it is believed that there exists a Roman

bell-pit working as a stone quarry. At Ham Hill near Stoke-sub-Hamdon in Somerset (Ham Hill

Quarries) Ham Hill Stone (an oolitic limestone) was quarried for use as a Roman building stone (MPP

Step 3 1999).